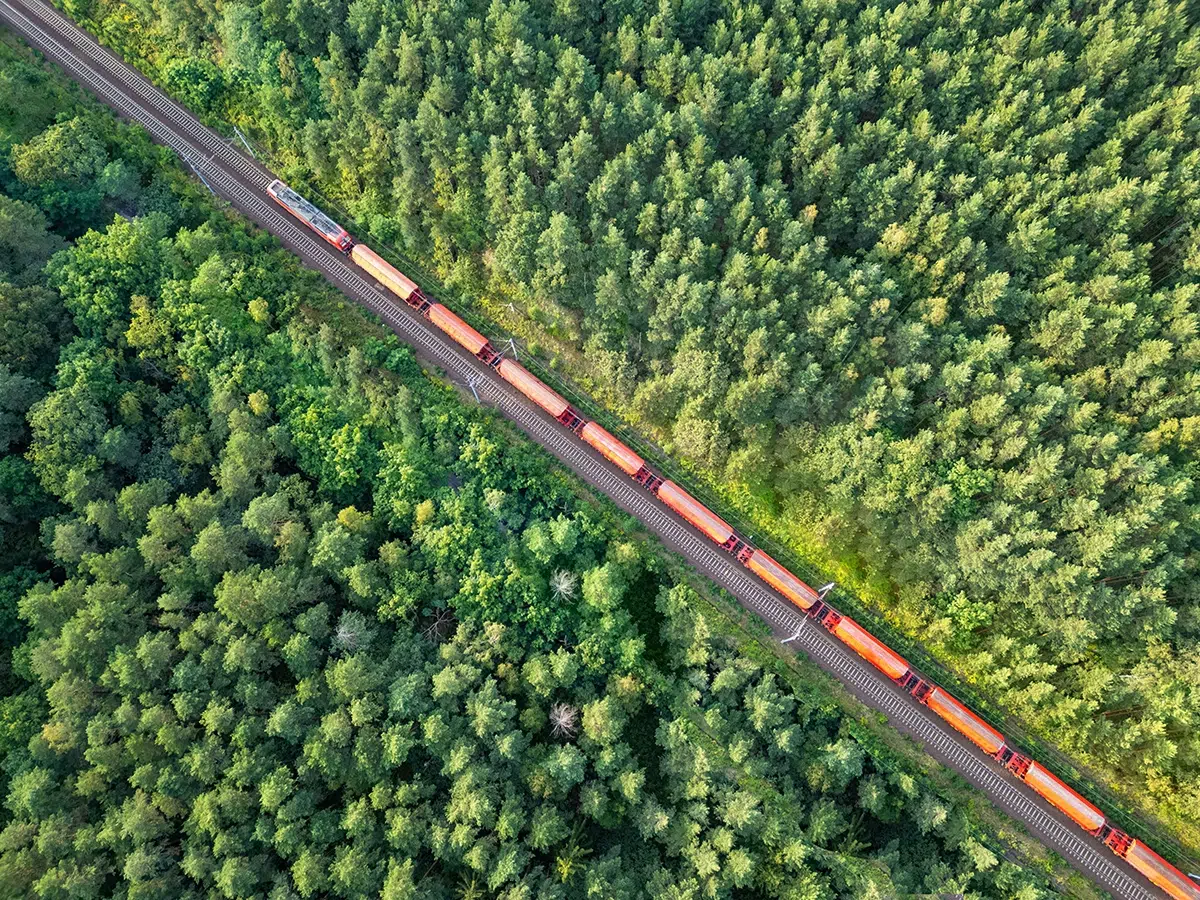

For rail operators, the challenge isn’t just moving passengers or cargo efficiently, it’s doing so while maintaining real-time visibility, operational safety, and cost control. On high-density routes, connectivity demands surge as operators rely on IoT sensors, predictive maintenance systems, and centralized monitoring. Traditional solutions often lead to skyrocketing expenses, inefficient resource allocation, and complex management overhead. So, how can passenger and freight rail operators keep trains moving and goods secure without breaking the budget?

Pain Points Driving Up Costs for Freight Rail

- Unpredictable Bandwidth Expenses

Rail operations increasingly depend on data-heavy applications, which help with tracking passengers and cargo, monitoring wayside equipment, and running analytics. Without intelligent bandwidth management, costs spiral out of control.

- Complex Network Deployments Across Large Fleets

Managing connectivity for hundreds of locomotives and remote assets is time-consuming and expensive.

- Downtime and Service Interruptions

Every minute of lost connectivity impacts scheduling, cargo visibility, and customer SLAs, leading to hidden costs in delays and penalties.

- Cybersecurity Risks

Protecting critical infrastructure from evolving threats adds another layer of cost and complexity.

Smart Strategies to Reduce Costs

Cutting costs doesn’t mean cutting corners. It means optimizing resources, leveraging technology, and simplifying operations. Here’s how rail operators can achieve this:

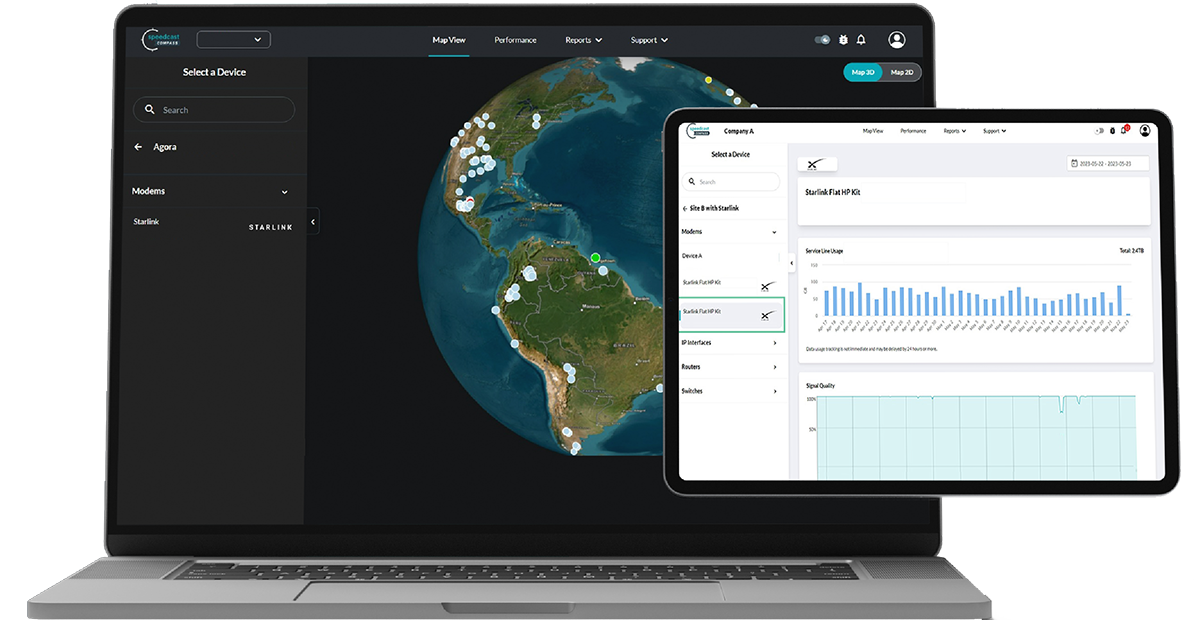

1. Deploy Smart Edge Management with SIGMA

The SIGMA Ecosystem is designed to streamline operations and reduce overhead for rail:

- Centralized Remote Management: Update software, apply security patches, and monitor performance from one platform.

- Templated Deployments: Roll out configurations across multiple locomotives and wayside devices simultaneously, saving time and labor costs.

- Multi-Path Network Management: Balance traffic intelligently between terrestrial networks in urban areas and satellite connectivity (Starlink, OneWeb, and future Amazon Leo) in remote regions to prevent throttling and keep bandwidth costs predictable.

- Zero-Trust Security: Avoid costly breaches with built-in compliance and authentication.

2. Optimize Crew Connectivity and Operational Apps

Whether on passenger routes or freight lines, passengers and crew members onboard require connectivity for safety and operational applications. Speedcast solutions help:

- Reliable Service: Speedcast manages connectivity end-to-end, so your team focuses on rail operations, not troubleshooting.

- Bandwidth Control: Prioritize mission-critical applications over non-essential traffic to avoid unnecessary costs.

3. Leverage Satellite Solutions for Cost Efficiency

When cellular coverage is patchy or expensive, satellite connectivity becomes essential for freight corridors:

- Starlink for Rail

- Lower Cost per GB than cellular in many markets.

- High-Speed Performance: Up to 500 Mbps now, scaling to 1 Gbps by 2026.

- Rail-Optimized Hardware: Lightweight, low-profile terminals tested at speeds up to 400 mph.

- 9% SLA: Minimize costly downtime and maintain cargo visibility.

- Eutelsat OneWeb enabled by Kymeta

- Global Coverage with low latency (~200 ms RTT).

- Ideal for Forward-Heavy Traffic: Great for telemetry, IoT data, and operational apps.

- Improving Reliability: Short outages will decrease as constellation expands.

Driving Rail Forward

Cost control on rail routes starts with smarter connectivity strategies. By combining SIGMA’s intelligent edge management, Speedcast’s global services, and satellite solutions like Starlink and OneWeb, rail operators can:

- Reduce bandwidth costs.

- Simplify deployments across large fleets.

- Minimize downtime and penalties.

- Maintain passenger and cargo visibility and operational safety without overspending.

Ready to cut costs and boost performance?

Explore how Speedcast and SIGMA can transform your freight rail operations today.